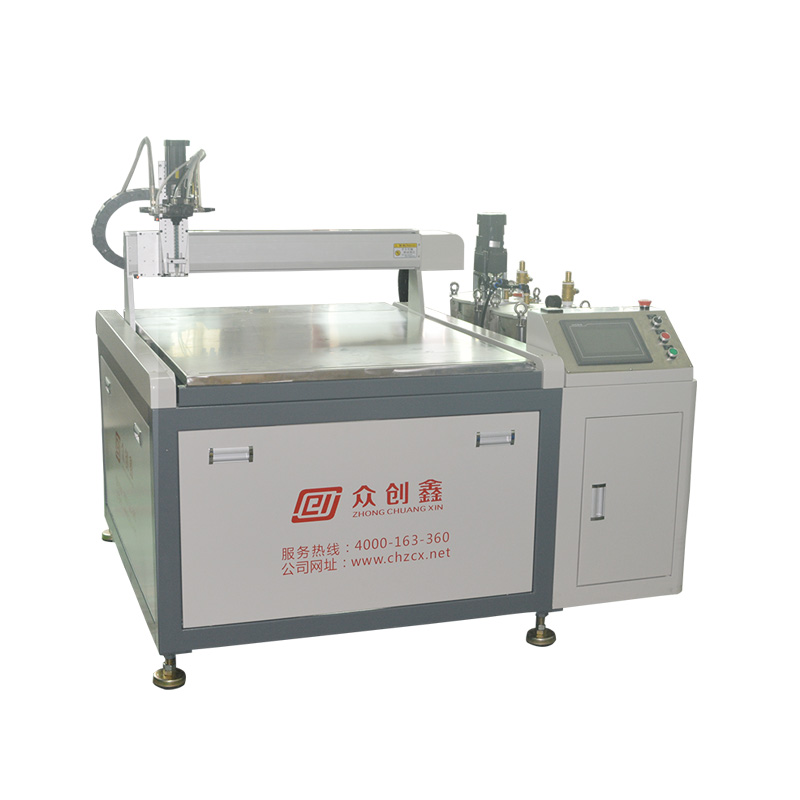

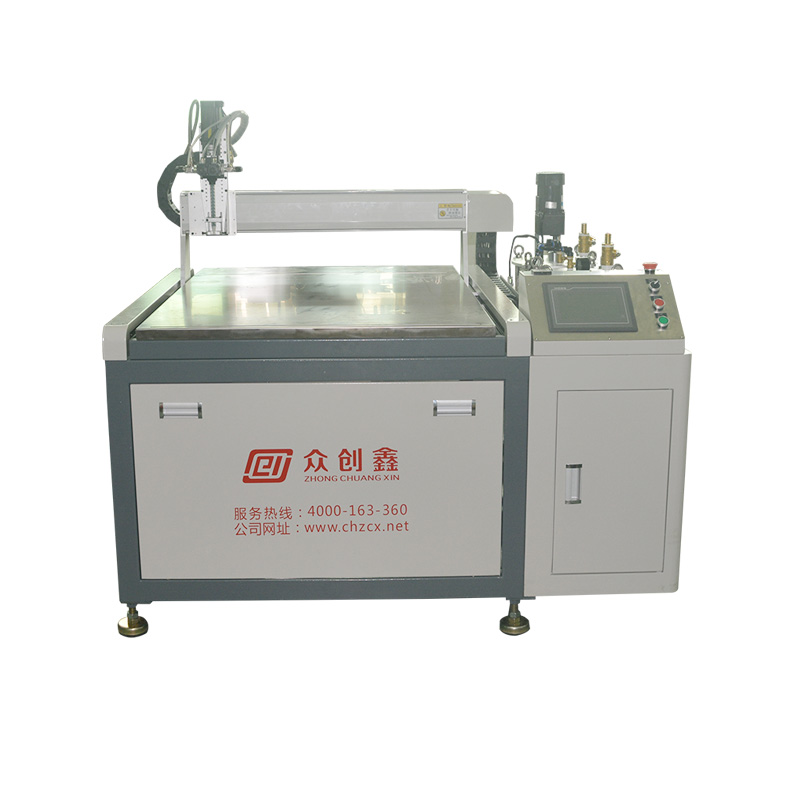

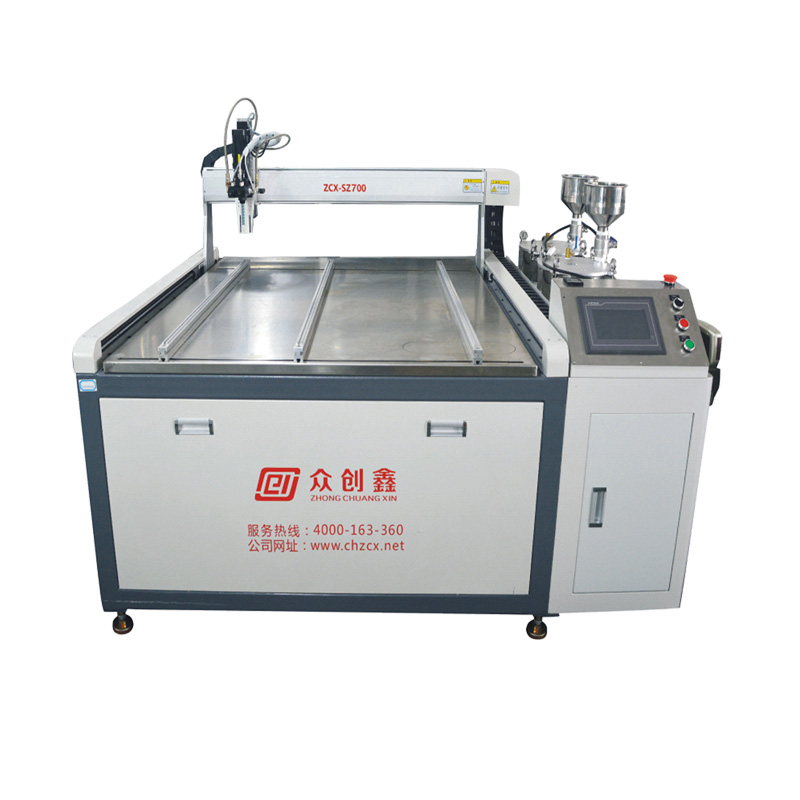

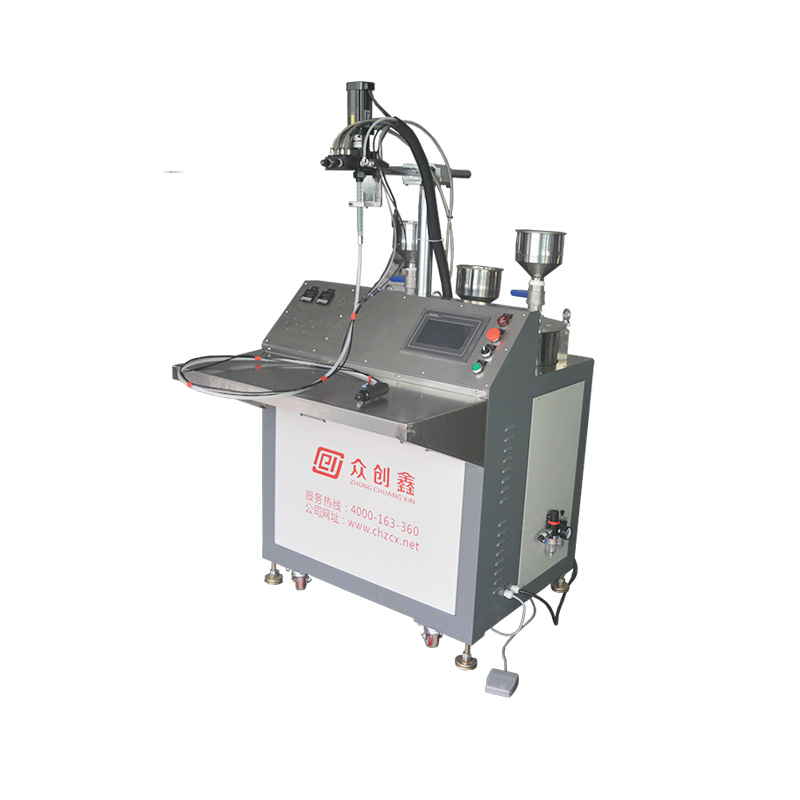

The characteristics of ZCX table glue machine:

1.Accurate positioning, high accuracy, small operation error: solid square steel welding platform, large gantry milling and processing, guarantee platform precision;High precision grinding grade, high precision grinding grade slide rail, high precision grinding grade sliding block, high precision balancing device and Japanese imported mitsubishi servo motor are adopted to ensure high efficiency and high efficiency.

2.Powerful electronic control system: imported panasonic PLC, original motor, touch screen, electronic components, wiring, dustproof, antistatic system are designed according to national standard.

3.It is the perfect combination of high wear and wear screw pump with high precision high maintenance pressure gear pump. It can make full use of its advantages, and make a new technological breakthrough for the ratio of glue and high ratio glue.A gel is not corrosive, it has impurities, and the screw pump can supply the high glue quantity.B glue is corrosive, no impurity, the gear pump can achieve high corrosion resistance and high pressure.

4.A and B glue level alarm function: can prevent the appearance of the phenomenon in time.

5.The original timing system: prevent the shift, stop the temporary stop the glue, lead the glue operation time, resulting in the mixing system glue solidify, unlimited delay operation time.

6.B rubber curing agent: prevent the problem of glue that occurs when glue is broken.

7.Multiple filtration system: glue from the plastic drum to the rubber head, use multiple filtration, prevent the inside of the glue barrel into the impurity caused the card pump.

8.Equipped with A rubber heating device and A low temperature environment, heating can increase glue fluidity.

9.Automatic cleaning system: the machine adopts the split separation method, only to mix at the top of the gluing head. After use, automatic cleaning, the operation is quick and convenient.

10.With the integration of glue and glue, automatic operation.

11.Easy to operate, can store 0-1000 sets of parameters, produce the product parameters when production, press start key.

Equipment parameters:

Ratio of glue to glue: ratio between 1:1 and 10:1

Machine stroke: 1000*1000*30mm can be customized according to customer\'s actual needs

Operating speed: 250mm/s (displacement)

Operating accuracy: plus or minus 0.02mm (displacement)

Running track: point, line, box, circle, circle, and graphical import

Speed of filling: 10-150g/5s adjustable (out of glue, depending on proportion and characteristics of glue)

Adhesive accuracy: the amount of glue is plus or minus 1%, the ratio: plus or minus 1%

Input pressure range: 0.5-0.8MPa

Compression of head seal: MAX is less than 2.6Mpa

Viscosity: <10000CPS

Operation mode: automatic and manual

Programming: teaching programming

Electronic control system: intelligent motion control card +PLC+ control panel (program setting, modification, storage, etc.)

Glue cutoff system: A, B rubber independent instantaneous automatic return system

Mixed mixing system: high speed dynamic mixing device

Control of glue proportion: high precision metering pump

A pump: high precision and high wear-resisting screw pump 6-12cc (can be specified)

B pump: high precision high-maintenance pressure gear pump 0.6-2.4CC (can be specified)

A plastic drum capacity: 22L

B plastic drum capacity: 22L

Cleaning capacity: 10L

Dimensions: 1765*1350*1350mm

Rated power: 220V 50Hz about 3500W

Scope of application:

The equipment is suitable for high efficiency, high operation precision and high glue ratio production process.The main application is: table stick, straight - screen, waterproof power, resistance, capacitor and other industries.

Traditional artificial irrigation has many disadvantages:

1. The amount of glue is not uniform, completely manual operation, the ratio is not allowed, the glue quantity is uneven, the product qualification rate is reduced.

2. The speed of artificial irrigation is slow, and the output can not be raised.

3. It is difficult to recruit and manage.

4. The waste of glue caused by pure labor is great.